LNG Marine Terminal and Multi-Purpose Pier EIA Review

Introduction

In July 2001, Irving Oil Limited officially registered for screening a project proposal to construct and operate a liquid natural gas (LNG) marine terminal and multi-purpose pier. The purpose of the project was to receive and store LNG unloaded from takers, regassify the LNG into natural gas, and deliver the natural gas to a pipeline. The project was designated to take place at the Canaport facility near St-John, New Brunswick. This deep water oil terminal has been owned and operated by Irving since 1970. This project would place Irving among the 39 LNG import and 16 export terminals worldwide.

On December 14, 2001 the Minister of the Environment and the Local Government determined that the project required the completion of an EIA. A comprehensive study was to be completed in accordance with CEAA (Canadian Environmental Assessment Act), the Clean Environment Act, and the Environmental Impact Assessment Regulation. According to the EIA report : “[t]he purpose of the Environmental Impact Statement (EIS) is to assess the significance of potential environmental effects of the proposed Project to the receiving environment, and to identify methods of optimizing positive environmental effects and reducing adverse environmental effects that may result from the Project.”

After a self-imposed break in the environmental impact assessment in order to complete a feasibility study, in October 2003 the project was altered in order to include the capacity to receive and unload Orimulsion (trade name for emulsified bitumen) tankers to tanks. After this, a new terms of reference were drafted, presented in the public, and this modification was also included in the EIA.

The preparation of the EIS was contracted out to a consulting firm, Jacques Whitford Environment Limited. They were to be managed by Fundy Engineering and Consulting Limited on behalf of Irving. Jacques Whitford was also assisted by ADI Limited, Daniel K. Gleen & Associates, as well as Quest Consultants Inc. Additionally, in order to complete the EIA, the provincial Minister of Environment as well as the Local Government appointed a Technical Review Committee (TRC) that was comprised of specialists from numerous Government agencies at all levels but the Provincial Department of the Environment and the Local Government were the lead agencies involved in the review. The TRC was established in order to harmonize the federal-provincial review for the EIA. Specifically, the harmonization was to ensure that the public and the proponent were provided with a simplified processed in order to avoid confusion and duplication. The National Energy Board was to look over the findings of the TRC.

Ultimately, the decision regarding the project was left to the Minister of the Environment and the Cabinet. As such, in August 2004, the Minister of the Environment, Stéphane Dion announced that the project had been accepted as it had been determined that it was not likely to cause significant adverse environmental effects. According to a news release made public on August 6, 2004, the Minister based his decision on the following:

- the comprehensive study report, including the conclusions and recommendations submitted by the responsible authorities, Fisheries and Oceans Canada, Environment Canada and Transport Canada;

- public comments received during the consultation period on the comprehensive study report and the responsible authorities' response to these comments;

- the implementation of mitigation measures identified in the report; and

- the implementation of a follow-up program.

Proponent

Of vital significance to this project is the proponent. Though Irving Oil Limited is a family owned company founded in 1924 in New Brunswick, it is now often referred to as an empire. Currently, the Irving Group is composed of over 300 companies ranging from pulp and paper mills to gas stations to ship yards. Irving is also known for its vertical expansion. This means that Irving buys or establishes both customers and suppliers within an industry. For example, in order to retail their lumber, Irving has established a hardware/lumber yard chain called Kent building and supplies. Additionally, they have set up Kent homes, a company that uses the lumber to make prefabricated homes that are sent all over the region. Notably, Irving owns Canada’s largest oil refinery, and in 2001 accounted for 75% of Canada’s petroleum exports and over 31% of New Brunswick’s total exports.

In discussing Irving’s role in the area, one of the major issues that arises is the economic stranglehold which they have established. Legislation has even been passed in other parts of the Maritimes limiting their expansion. They employ approximately 1 in 12 people in New Brunswick. Also, Irving is the owner and de facto editor of every English-language news paper in the province as well as the owner of a substantial portion of the French-language newspapers. As the maxim holds, “freedom of the press is for those who own one.” This near-monopoly has been noted to have played a role in public perception of the company particularly in terms of labour disputes which have arisen in the past.

More positively, according to their website, Irving has been working towards environmental progress. They are ardent supporters of the ratification of the Kyoto accord and are working on setting up wind farms. Additionally, they have set up a 600 acre nature reserve in New Brunswick.

Project Description

The Project was proposed by Irving Oil Limited. The proposal included developing a Liquefied Natural Gas (LNG) Marine Terminal and Pier at Irving Canaport facility. As mentioned in the introduction, the project will take place in near Saint-John in New Brunswick, only 60 miles from the US border.

Project location

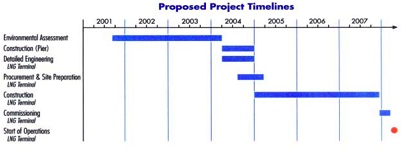

Project timeline

To complement the region’s existing energy resource infrastructure, Irving Oil Limited wants to add LNG capability to its deepwater oil terminal at Irving Canaport. It was determined that LNG is easier to transport and to store than regular Natural Gas. When cooled to -161°C Natural Gas starts to condense and takes form of LNG. Thus its volume is greatly reduced and it becomes a more economically feasible product. LNG does not escape easily and more of it can be transported at a time.

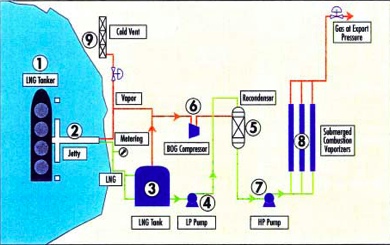

The LNG Project includes necessary infrastructures to receive and unload Orimulsion tankers to tanks. All of the necessary infrastructures are shown on the image below. The purpose of the LNG facilities is to receive LNG (2), store LNG (3), regassify LNG into NG (5) and deliver Natural Gas to pipelines. As mentioned, the pier will also serve for the offloading of Orimulsion from tankers.

LNG infrastructure

LNG science

The process is a liquefaction (from gas phase to liquid phase). At first, hydrogen sulfide, water and carbon dioxide have to be removed from the natural gas because it would freeze during the process and would be a corrosive factor during the transportation and storage phase. This purified gas is then liquefied at -163°C (-260°F). The final liquid is primarily methane.

The process is a liquefaction (from gas phase to liquid phase). At first, hydrogen sulfide, water and carbon dioxide have to be removed from the natural gas because it would freeze during the process and would be a corrosive factor during the transportation and storage phase. This purified gas is then liquefied at -163°C (-260°F). The final liquid is primarily methane.

LNG characteristics are very interesting. Gas/Liquid ratio is 610. It means that “One LNG tanker can transport enough LNG to equal 610 tankers carrying natural gas at atmospheric pressure and temperature”. We can understand how cost-efficient it is to transport the liquid form over long distances where pipelines do not exist.

- LNG density is 448.108 kg/m3. Water being 1000 Kg/m3, LNG will float on water.

- LNG energy content is 88.1 British Thermal Unit/Gallon. Diesel being 140.5 BTU/ Gallon, LNG energy density is 60% of diesel one.

- LNG is odorless, colorless, non-corrosive, non toxic, not explosive and has low carbon dioxide emissions.

- LNG cannot burn in its liquid phase. For LNG to burn, it must first vaporize, then mix with air in the proper proportions (10% to 15%) and then be ignited, which is very rare.

LNG storage requires a very efficient insulation as it has to be kept at a very low temperature (-163°C). Therefore the advanced generation of tankers have a double layer inner shell with a 9% nickel alloy.

LNG storage requires a very efficient insulation as it has to be kept at a very low temperature (-163°C). Therefore the advanced generation of tankers have a double layer inner shell with a 9% nickel alloy.

As no insulation system is perfect a “Boil-Off” effect exists during transit. This gasification will keep the storage cold (there is an auto-refrigeration effect at the boiling point — vaporization uses heat, it costs energy), it can be used as a vessel fuel or can be re-liquifified upon arrival.